Digital Twins in Design

Dynamic data models of physical assets transforming the built world

The intersection of technology and healthcare facility architecture continually redefines the possibilities of modern medical environments. As digital tools become more integrated into design and planning processes, healthcare space conception, construction, and management are transforming. These advancements are not merely about keeping pace with innovation; they are reshaping how hospitals, clinics, and specialized care centres are built, maintained, and monitored to enhance patient care and ensure long-term operational efficiency.

A key example of this technological shift is the adoption of digital twin technology. This tool allows design teams, owner stakeholders, and contractors to gain unprecedented visibility into space utilization, maintenance requirements, and potential design challenges before they arise. Such technologies pave the way for more informed decision-making and streamlined project execution, setting a new standard for healthcare architecture.

Exploring and embracing emerging technologies is essential for design teams aiming to remain competitive and adaptable. By adopting forward-thinking tools and methods, firms can streamline workflows, deliver better outcomes, and keep pace with the rapidly evolving demands of the healthcare design landscape.

3-D Scans for Conceptual Design

Traditionally, capturing spatial data for conceptual design involved manual measurements with pen and paper or basic laser measuring tools. While effective in their time, these methods were labor-intensive and prone to oversight, often missing critical spatial relationships or hidden conditions within complex healthcare environments.

The adoption of 3-D scanning technology has revolutionized this process, offering precision, speed, and comprehensiveness in data collection. Selecting the right tool depends on several factors, including training requirements, equipment cost, data capture precision, scanning speed, stealth, accessibility in occupied spaces, and how well the captured data is organized for stakeholder access. These considerations help design teams determine the most effective technology for each project phase, type, and size.

Complex Construction History

Healthcare facilities often evolve over decades, resulting in layered construction histories that can be challenging to unravel. Additions and renovations, sometimes poorly documented, create an intricate tapestry of infrastructure. Traditional as-built drawings frequently lack critical information like the location of furniture, equipment, or hidden structural elements.

3-D scanning and digital twin technologies allow design teams to visualize and understand these complexities, providing a real-time, interactive representation of the space. This level of insight significantly reduces risks during renovation and expansion projects by revealing structural interferences and outdated configurations that might otherwise go unnoticed.

Out-of-the-Box Solutions

While many scanning technologies are marketed toward industries like construction, agriculture, and property management, their application in healthcare design is often overlooked. This represents a unique differentiation opportunity for both owners and designers in environments where accuracy and efficiency directly impact patient care and operational safety.

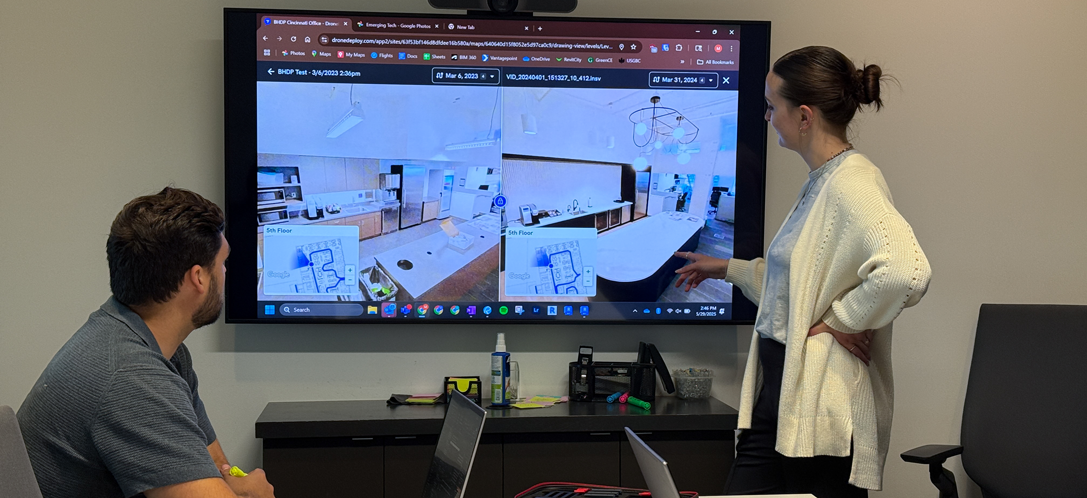

Forward-looking design teams are exploring tools not traditionally aimed at architecture, such as DroneDeploy, NavVis, and Matterport, to unlock new possibilities in space planning, facility assessment, and ongoing facility monitoring. These solutions streamline data capture, enhance spatial understanding, and support proactive decision-making throughout the life cycle of healthcare environments, from planning and design to long-term maintenance and operational oversight.

Evaluating Scanning Technologies

Different scanning technologies offer distinct advantages depending on project requirements. DroneDeploy allows rapid 360-degree walk-throughs of expansive areas, capturing visual context with minimal setup. NavVis scanners, while heavier and costlier, provide high-precision measurements ideal for projects requiring exact spatial data. Matterport scanners strike a balance, offering immersive client walk-throughs with clear visuals, though they require a more deliberate setup with a tripod.

The time investment for each method varies. Traditional pen and paper surveys capture around two to four square metres (21 to 42 SF) per minute, while Matterport can achieve around 7.7 square metres (83 SF) per minute. DroneDeploy far surpasses these, covering around 92 square metres (1,000 SF) per minute, and NavVis follows closely at 70 square metres (750 SF) per minute. Many site-specific factors can cause these estimates to vary.

It’s essential to evaluate the right tool for a project based on the space’s unique conditions, priorities, and constraints. For example, a large hospital campus undergoing initial programming may benefit from DroneDeploy’s high-speed, immersive walk-throughs for assessing look and feel across many departments without the need for measurable accuracy. In contrast, a renovation project within an active surgical suite may require the high precision of NavVis to verify clearances and compliance with infection control guidelines. Choosing the right scanning solution from the start not only improves workflow efficiency but also ensures the data collected aligns with the project’s intended outcomes and balance of team resources.

Choosing the right scanning tool requires multiple considerations: the size of the area, how quickly results are needed and how the data will be used.

Features Enabled by Digital Twins

Digital twins enhance project planning by validating space characteristics, ensuring compliance with hospital standards, and supporting user request evaluations against documented guidelines. They can also be instrumental in identifying discrepancies early in the design process, helping to avoid costly rework or miscommunication.

Beyond design, this technology serves as an ongoing operational tool. Facilities teams can remotely monitor space usage, track equipment placement, and assess compliance with safety standards over time. For example, the models can quickly highlight storage areas where medical supplies or hazardous materials may be improperly placed, or confirm that workstations meet ergonomic and infection prevention guidelines. This continuous oversight contributes to a safer and more organized environment for both staff and patients.

Another often overlooked advantage is the ability of models to house critical documentation, such as product cut sheets, operation manuals, and equipment data. Traditionally, this information is scattered across physical binders, hard drives, or remote storage locations, making it difficult and time-consuming to access. Housing these documents within a centralized, visual model provides users with a much more intuitive way to locate and reference technical data, improving maintenance efficiency and reducing the risk of lost information over time.

Another key benefit is the reduction in repeated physical site visits. In large healthcare campuses, walking across a facility to validate a condition can be time-consuming. This challenge grows in multi-site systems, where travelling to remote locations for basic observations can significantly drain time and resources. With an accurate, interactive environment representation, teams can eliminate this travel burden. This saves hours of labor and enables quicker response times and more informed decision-making, which is especially valuable in the fast-paced world of healthcare operations.

By visualizing spaces remotely, teams can align quickly, resolve questions on the spot and keep projects moving without stepping foot on-site.

The Future of Living Models

Looking forward, these models are evolving into living, dynamic systems. When paired with real-time sensors and integrated data streams, they can begin to reflect ongoing building performance — monitoring HVAC systems, energy usage, and internal conditions like temperature or humidity. This creates a powerful feedback loop for sustainability, helping reduce carbon footprints while improving patient and staff comfort.

Integration with building information modelling, asset tagging, and continuous 3-D scan data allows for an always up-to-date model, offering accurate insight for operational adjustments and long-term planning. As the technology matures, these tools are becoming essential components in managing the full life cycle of healthcare spaces, from design to occupancy to everyday operations. This is reshaping not only how environments are built but also how they are continuously experienced and optimized.

Additionally, the rapid advancement of smartphone technology is democratizing access to spatial data capture. Increasingly powerful mobile devices now support high-resolution light detection and ranging (LiDAR) and photogrammetry applications, enabling individuals and smaller teams to generate digital building copies with minimal equipment investment. This accessibility is lowering the barrier to entry for organizations exploring digital twins, making it more feasible to integrate the technology across a broader range of healthcare environments, regardless of scale or budget. In time, these tools may become as ubiquitous as floor plans, serving as foundational resources for day-to-day operations and strategic planning alike.

Digital twins enable users to navigate a space remotely, with overlaid floor plans that support quick orientation and spatial understanding, which is especially helpful for off-site teams.

Embracing The Paradigm Shift

The integration of 3-D scanning and digital twin technologies is transforming not only how healthcare facilities are designed but also how they are understood, maintained, and optimized long after construction. These tools have shifted from documentation aids to essential platforms for communication, planning, and real-time facility oversight.

By enabling remote validation of spaces, streamlining data access, and facilitating collaboration among stakeholders, digital replicas reduce inefficiencies and improve responsiveness across departments. As they evolve into living models, their potential to support sustainability, energy management, and occupant comfort will only expand.

This convergence of design and operational intelligence is setting a new standard in healthcare architecture, one where facilities are more adaptive, staff are better supported, and patient outcomes are prioritized through more intelligent, data-driven environments.

This article was originally published in Canadian Healthcare Facilities.

To learn more about how innovative technology can meet today’s challenges and drive positive outcomes for the future in healthcare, fill out the form below.

Author

Content Type

Published Articles

Date

August 13, 2025

Market

Practice

Topic

Technology

Innovation